[{"CategoryId":271,"CategoryName":"By Series","ParentId":0,"Imageurl":""},{"CategoryId":272,"CategoryName":"By Size","ParentId":0,"Imageurl":""},{"CategoryId":273,"CategoryName":"By Number of Pins","ParentId":0,"Imageurl":""},{"CategoryId":274,"CategoryName":"By Application","ParentId":0,"Imageurl":""},{"CategoryId":275,"CategoryName":"By Wiring","ParentId":0,"Imageurl":""},{"CategoryId":276,"CategoryName":"Customization","ParentId":0,"Imageurl":""},{"CategoryId":277,"CategoryName":"By Material","ParentId":0,"Imageurl":""},{"CategoryId":278,"CategoryName":"LP Series","ParentId":271,"Imageurl":"2025/07/20250724101928371.jpg?TFDns7vliJcuYmlwLjI1NTUuanBn"},{"CategoryId":1319,"CategoryName":"SF Series","ParentId":271,"Imageurl":"2025/09/20250913181601452.jpg?U0Y2LTgtMTDlhajlrrbnpo8uanBn"},{"CategoryId":1245,"CategoryName":"SP Series","ParentId":271,"Imageurl":"2025/09/20250913181428839.jpg?U1AuanBn"},{"CategoryId":279,"CategoryName":"Self Locking Series","ParentId":271,"Imageurl":"2024/09/20240905134920982.png?U2VsZiBMb2NraW5nIFNlcmllcw=="},{"CategoryId":280,"CategoryName":"Waterproof Cable Connector","ParentId":271,"Imageurl":"2024/09/20240905142754587.png?V2F0ZXJwcm9vZiBDYWJsZSBDb25uZWN0b3I="},{"CategoryId":281,"CategoryName":"Junction Box","ParentId":271,"Imageurl":"2024/09/20240905155939966.png?5o6l57q/55uS57O75YiXIDYxM3g2MTMucG5n"},{"CategoryId":1222,"CategoryName":"Cable Gland","ParentId":271,"Imageurl":"2025/03/20250320135315907.jpg?Y2FibGUtZ2xhbmQuanBn"},{"CategoryId":282,"CategoryName":"Energy Storage Connector","ParentId":271,"Imageurl":"2024/09/20240905143234262.png?RW5lcmd5IFN0b3JhZ2UgQ29ubmVjdG9y"},{"CategoryId":1161,"CategoryName":"PV Connector","ParentId":271,"Imageurl":"2024/09/20240905143119031.png?UFYgQ29ubmVjdG9y"},{"CategoryId":1351,"CategoryName":"M29","ParentId":272,"Imageurl":""},{"CategoryId":1170,"CategoryName":"M28","ParentId":272,"Imageurl":"2024/12/20241204113448729.png?TTI4IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1169,"CategoryName":"M25","ParentId":272,"Imageurl":"2024/12/20241204113352959.png?TTI1IGNpcmN1bGFyIHBsYXN0aWMgd2lyZSBjb25uZWN0b3I="},{"CategoryId":319,"CategoryName":"M24","ParentId":272,"Imageurl":"2024/12/20241204113237802.png?TTI0IEluZHVzdHJpYWwgd2F0ZXJwcm9vZiBjb25uZWN0b3I="},{"CategoryId":1168,"CategoryName":"M23","ParentId":272,"Imageurl":"2024/12/20241204112141563.png?TTIzIHdhdGVycHJvb2YgcGx1ZyBjb25uZWN0b3Jz"},{"CategoryId":1350,"CategoryName":"M21","ParentId":272,"Imageurl":""},{"CategoryId":318,"CategoryName":"M20","ParentId":272,"Imageurl":"2024/12/20241204112034702.png?TTIwIGNpcmN1bGFyIGNvbm5lY3Rvcg=="},{"CategoryId":1167,"CategoryName":"M19","ParentId":272,"Imageurl":"2024/12/20241204111937164.png?TTE5IHdhdGVycHJvb2Ygd2lyZSBjb25uZWN0b3Jz"},{"CategoryId":1349,"CategoryName":"M17","ParentId":272,"Imageurl":""},{"CategoryId":293,"CategoryName":"M16","ParentId":272,"Imageurl":"2024/12/20241204111827969.png?TTE2IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1166,"CategoryName":"M15","ParentId":272,"Imageurl":"2024/12/20241204111717740.png?TTE1IG1hbGUgYW5kIGZlbWFsZSBjb25uZWN0b3Jz"},{"CategoryId":1348,"CategoryName":"M13","ParentId":272,"Imageurl":""},{"CategoryId":292,"CategoryName":"M12","ParentId":272,"Imageurl":"2024/12/20241204111548642.png?TTEyIFdhdGVycHJvb2YgTTEyIENvbm5lY3Rvcg=="},{"CategoryId":1347,"CategoryName":"M10","ParentId":272,"Imageurl":""},{"CategoryId":1346,"CategoryName":"M8","ParentId":272,"Imageurl":""},{"CategoryId":1345,"CategoryName":"M6","ParentId":272,"Imageurl":""},{"CategoryId":335,"CategoryName":"TYPE-C","ParentId":273,"Imageurl":"2024/08/20240803175816209.jpg?TFAxNi1UWVBFLUPph5HlsZ7ms5XlhbAuanBn"},{"CategoryId":334,"CategoryName":"Fiber","ParentId":273,"Imageurl":"2024/07/20240730100446602.png?TFAyNC1GSUJFUig2KSAyMDB4MjAwIC0g5Ymv5pysLnBuZw=="},{"CategoryId":333,"CategoryName":"HDMI","ParentId":273,"Imageurl":"2024/07/20240730100616849.png?TFAyNC1IRE1JKDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":332,"CategoryName":"USB","ParentId":273,"Imageurl":"2024/07/20240730100646405.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":331,"CategoryName":"RJ45","ParentId":273,"Imageurl":"2024/07/20240730100713409.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlr7nmjqUucG5n"},{"CategoryId":1335,"CategoryName":"26 Pins","ParentId":273,"Imageurl":"2025/09/20250908170725350.jpg?U1AyOS0yNlDkuKTlrZTluqfmraPoo4UgODAweDgwMC5qcGc="},{"CategoryId":330,"CategoryName":"24 Pins","ParentId":273,"Imageurl":"2024/07/20240730101220115.jpg?TFAyNC0yNFDpnaLmnb/ph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1334,"CategoryName":"20 Pins","ParentId":273,"Imageurl":"2025/09/20250908170702461.jpg?U0YyOC0yMFDpnaLmnb8gODAweDgwMC5qcGc="},{"CategoryId":329,"CategoryName":"19 Pins","ParentId":273,"Imageurl":"2024/07/20240730101243254.jpg?TFAyNC0xOVDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1333,"CategoryName":"18 Pins","ParentId":273,"Imageurl":"2025/09/20250908170641433.jpg?U0YyOC0xOFDlr7nmjqUgODAweDgwMC5qcGc="},{"CategoryId":1344,"CategoryName":"17 Pins","ParentId":273,"Imageurl":""},{"CategoryId":1332,"CategoryName":"16 Pins","ParentId":273,"Imageurl":"2025/09/20250908170620266.jpg?U0YyOC0xNlDpnaLmnb/luqflj43oo4UgODAweDgwMC5qcGc="},{"CategoryId":1215,"CategoryName":"14 Pins","ParentId":273,"Imageurl":"2024/08/20240808120100973.jpg?TFAyMC0xNFDms5XlhbDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":328,"CategoryName":"12 Pins","ParentId":273,"Imageurl":"2024/07/20240730101400996.png?TFAyNC0xMlDms5XlhbDloZHmlpnlj43oo4XmrL4ucG5n"},{"CategoryId":327,"CategoryName":"10 Pins","ParentId":273,"Imageurl":"2024/07/20240730101422023.jpg?TFAyNC0xMFDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":326,"CategoryName":"9 Pins","ParentId":273,"Imageurl":"2024/07/20240730101545901.jpg?TFAyMC05UC3lr7nmj5ItMy5qcGc="},{"CategoryId":325,"CategoryName":"8 Pins","ParentId":273,"Imageurl":"2024/07/20240730101729864.jpg?TFAxNi04UOmdouadv0zph5HlsZ7mraPoo4UuanBn"},{"CategoryId":324,"CategoryName":"7 Pins","ParentId":273,"Imageurl":"2024/07/20240730101805407.jpg?TFAxNi03UOazleWFsFDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":323,"CategoryName":"6 Pins","ParentId":273,"Imageurl":"2024/07/20240730101848277.png?TFAxMi02UCDlj43oo4UgMi5wbmc="},{"CategoryId":322,"CategoryName":"5 Pins","ParentId":273,"Imageurl":"2024/07/20240730102001465.jpg?TFAyNC01UOWFrOaPklPph5HlsZ7lj43oo4XplIHnur/mrL4uanBn"},{"CategoryId":321,"CategoryName":"4 Pins","ParentId":273,"Imageurl":"2024/07/20240730102053511.png?TFAyMC00UOazleWFsOWhkeaWmeato+ijhS5wbmc="},{"CategoryId":320,"CategoryName":"3 Pins","ParentId":273,"Imageurl":"2024/07/20240730102122414.jpg?TFAyOC0zUOWvueaPkuWhkeaWmeato+ijhS5qcGc="},{"CategoryId":295,"CategoryName":"2 Pins","ParentId":273,"Imageurl":"2024/07/20240730102152158.jpg?TFAyOC0yUOazleWFsOWhkeaWmeato+ijhS5qcGc="},{"CategoryId":294,"CategoryName":"1 Pin","ParentId":273,"Imageurl":"2024/12/20241202141836844.png?ZW5lcmd5IHN0b3JhZ2UgY29ubmVjdG9y"},{"CategoryId":315,"CategoryName":"Signal Connector","ParentId":274,"Imageurl":"2024/07/20240730133750759.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":297,"CategoryName":"Data Connector","ParentId":274,"Imageurl":"2024/07/20240730093457270.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":296,"CategoryName":"Power Connector","ParentId":274,"Imageurl":"2024/08/20240803175721975.jpg?TFAxNi00UCg5KS5qcGc="},{"CategoryId":338,"CategoryName":"Crimping Type","ParentId":275,"Imageurl":"2024/12/20241202143025954.png?TFAxMi0yUOWvueaPkumHkeWxnuato+ijhSA3NTB4NzUwLnBuZw=="},{"CategoryId":336,"CategoryName":"Solder Type","ParentId":275,"Imageurl":"2024/12/20241202142826795.png?TFAyNC0y6Iqv54SK5o6l5aGR5paZ5qy+5rOV5YWw5Y+N6KOFc2t1LnBuZw=="},{"CategoryId":337,"CategoryName":"Screw Type","ParentId":275,"Imageurl":"2024/12/20241202142506193.png?TFAxMi0yUOazleWFsFDph5HlsZ7plIHnur/lj43oo4UucG5n"},{"CategoryId":298,"CategoryName":"Screwless Type","ParentId":275,"Imageurl":"2024/05/20240529162027688.jpg?5b+r5o6l57O75YiXLmpwZw=="},{"CategoryId":301,"CategoryName":"Mix Pins","ParentId":276,"Imageurl":"2024/07/20240730102324120.jpg?TFAyOC0zUOazleWFsOWhkeaWmeato+ijhS0xLmpwZw=="},{"CategoryId":1330,"CategoryName":"Color","ParentId":276,"Imageurl":""},{"CategoryId":317,"CategoryName":"Metal + Plastic","ParentId":277,"Imageurl":"2024/08/20240803180032739.jpg?TFAxMi00UOazleWFsOmHkeWxnuWPjeijhS5qcGc="},{"CategoryId":316,"CategoryName":"All Metal","ParentId":277,"Imageurl":"2024/11/20241121135153910.png?TFAxMi0yUOazleWFsOasvumUgee6vy5wbmc="},{"CategoryId":300,"CategoryName":"All Plastic","ParentId":277,"Imageurl":"2024/08/20240803180224853.png?TFAxMi00UCDlj43oo4UgNy5wbmc="},{"CategoryId":287,"CategoryName":"LP12","ParentId":278,"Imageurl":"2024/12/20241203141919861.png?TFAxMiBlbGVjdHJpY2FsIHdhdGVycHJvb2YgY29ubmVjdG9ycw=="},{"CategoryId":283,"CategoryName":"LP16","ParentId":278,"Imageurl":"2024/12/20241203141926793.png?TFAxNiB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":286,"CategoryName":"LP20","ParentId":278,"Imageurl":"2024/12/20241203140522654.png?TFAyMCBJbmR1c3RyaWFsIHdhdGVycHJvb2YgY29ubmVjdG9y"},{"CategoryId":285,"CategoryName":"LP24","ParentId":278,"Imageurl":"2024/12/20241203140638274.jpg?TFAyNCB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":284,"CategoryName":"LP28","ParentId":278,"Imageurl":"2024/12/20241203140831377.png?TFAyOCBXYXRlcnByb29mIENhYmxlIENvbm5lY3Rvcg=="},{"CategoryId":303,"CategoryName":"M15MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095659595.jpg?TTE1TUYtM1AuanBn"},{"CategoryId":304,"CategoryName":"M19MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095626837.jpg?6Z2i5p2/55m95bqVIC0g5Ymv5pysLmpwZw=="},{"CategoryId":305,"CategoryName":"M23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095548936.jpg?RVctTTIzTVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":307,"CategoryName":"M28MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095408770.jpg?RVctTTI4TVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":306,"CategoryName":"P25MP/MF","ParentId":279,"Imageurl":"2024/07/20240729185729105.png?UDI1LS3oiq/mlbAt5aSW57q/55u05b6E5Zu+IDIwMHgyMDAucG5n"},{"CategoryId":1209,"CategoryName":"P23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730100244127.png?UDIzLnBuZw=="},{"CategoryId":302,"CategoryName":"Screw Connector Series","ParentId":280,"Imageurl":"2024/12/20241203142740551.png?U2NyZXcgQ29ubmVjdG9yIFNlcmllcw=="},{"CategoryId":289,"CategoryName":"Screwless Connector Series","ParentId":280,"Imageurl":"2024/09/20240905144436844.png?U2NyZXdsZXNzIENvbm5lY3RvciBTZXJpZXM="},{"CategoryId":290,"CategoryName":"2068 Serie","ParentId":281,"Imageurl":"2024/07/20240730094848584.png?RVctTTIwNjgtNVQucG5n"},{"CategoryId":1536,"CategoryName":"2068N Serie","ParentId":281,"Imageurl":"2026/01/20260116110540406.png?TTIwNjhOLTJUICAoMikucG5n"},{"CategoryId":1538,"CategoryName":"2068R Serie","ParentId":281,"Imageurl":"2026/02/20260206151256783.png?RVctTTIwNjhSLTFUICgxKS5wbmc="},{"CategoryId":308,"CategoryName":"2068S Serie","ParentId":281,"Imageurl":"2024/07/20240729190104148.jpg?55m95bqVMy5qcGc="},{"CategoryId":309,"CategoryName":"2068L Serie","ParentId":281,"Imageurl":"2024/07/20240729190043564.jpg?55m95bqVMi5qcGc="},{"CategoryId":310,"CategoryName":"2068XL Serie","ParentId":281,"Imageurl":"2024/07/20240730094724530.jpg?MTAuanBn"},{"CategoryId":1159,"CategoryName":"350A","ParentId":282,"Imageurl":"2024/07/20240729190329212.jpg?RTMwMC0zNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":1158,"CategoryName":"300A","ParentId":282,"Imageurl":"2024/07/20240729190349998.jpg?RTMwMOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":341,"CategoryName":"250A","ParentId":282,"Imageurl":"2024/07/20240729190408955.jpg?RTEwMC0yNTDlj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":340,"CategoryName":"200A","ParentId":282,"Imageurl":"2024/07/20240729190435882.jpg?RTI1MOS4jeWPr+aXi+i9rOieuuafsem7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":339,"CategoryName":"150A","ParentId":282,"Imageurl":"2024/07/20240729190456384.jpg?RTEwMC0yNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":311,"CategoryName":"120A","ParentId":282,"Imageurl":"2024/07/20240729190538607.jpg?RTI1MOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":312,"CategoryName":"100A","ParentId":282,"Imageurl":"2024/07/20240729190551775.jpg?RTEwMC0yNTDkuI3lj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":313,"CategoryName":"70A","ParentId":282,"Imageurl":"2024/07/20240729190619040.jpg?RTUw5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S6buR6Imy5aWX6KOFU0tVXy5qcGc="},{"CategoryId":314,"CategoryName":"50A","ParentId":282,"Imageurl":"2024/07/20240729190633170.jpg?RTUwLTcw5LiN5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S5qmZ6Imy5aWX6KOFU0tVLmpwZw=="},{"CategoryId":1533,"CategoryName":"LP20","ParentId":298,"Imageurl":""},{"CategoryId":1526,"CategoryName":"M25B","ParentId":298,"Imageurl":""},{"CategoryId":299,"CategoryName":"P25","ParentId":298,"Imageurl":"2024/05/20240529162134233.jpg?UDIzLjIuanBn"},{"CategoryId":1531,"CategoryName":"P23","ParentId":298,"Imageurl":""},{"CategoryId":1107,"CategoryName":"P20","ParentId":298,"Imageurl":"2024/09/20240909134224415.png?UDIwLS3oiq/mlbAt5aSW57q/55u05b6E5Zu+LSA2MTN4NjEzLnBuZw=="},{"CategoryId":1530,"CategoryName":"P25X","ParentId":298,"Imageurl":""},{"CategoryId":1529,"CategoryName":"P25T","ParentId":298,"Imageurl":""},{"CategoryId":1528,"CategoryName":"P20X","ParentId":298,"Imageurl":""},{"CategoryId":1527,"CategoryName":"P20T","ParentId":298,"Imageurl":""},{"CategoryId":1165,"CategoryName":"65A","ParentId":1161,"Imageurl":"2024/07/20240729190717746.jpg?MTBtbcKy6Z2i5p2/5bel5YW36Kej6ZSB5YWs5o+S5aS0LmpwZw=="},{"CategoryId":1164,"CategoryName":"45A","ParentId":1161,"Imageurl":"2024/07/20240729190731167.jpg?Nm1twrLnur/nq6/lt6Xop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1163,"CategoryName":"35A","ParentId":1161,"Imageurl":"2024/07/20240729190743086.jpg?NG1twrLnur/nq6/lt6Xlhbfop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1201,"CategoryName":"25A","ParentId":1161,"Imageurl":"2024/07/20240729190756464.jpg?Mi41bW3Csue6v+err+W3peWFt+ino+mUgeWFrOaPkuWktC5qcGc="},{"CategoryId":1223,"CategoryName":"PG Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1243,"CategoryName":"PG Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1224,"CategoryName":"M Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1244,"CategoryName":"M Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1247,"CategoryName":"SP13","ParentId":1245,"Imageurl":""},{"CategoryId":1246,"CategoryName":"SP17","ParentId":1245,"Imageurl":""},{"CategoryId":1327,"CategoryName":"SP21","ParentId":1245,"Imageurl":""},{"CategoryId":1326,"CategoryName":"SP29","ParentId":1245,"Imageurl":""},{"CategoryId":1320,"CategoryName":"SF6","ParentId":1319,"Imageurl":""},{"CategoryId":1321,"CategoryName":"SF8","ParentId":1319,"Imageurl":""},{"CategoryId":1328,"CategoryName":"SF10","ParentId":1319,"Imageurl":""},{"CategoryId":1322,"CategoryName":"SF12","ParentId":1319,"Imageurl":""},{"CategoryId":1323,"CategoryName":"SF16","ParentId":1319,"Imageurl":""},{"CategoryId":1324,"CategoryName":"SF20","ParentId":1319,"Imageurl":""},{"CategoryId":1325,"CategoryName":"SF28","ParentId":1319,"Imageurl":""}]

M12 Industrial Waterproof Connector In Robotic Applications-Robotics Industry

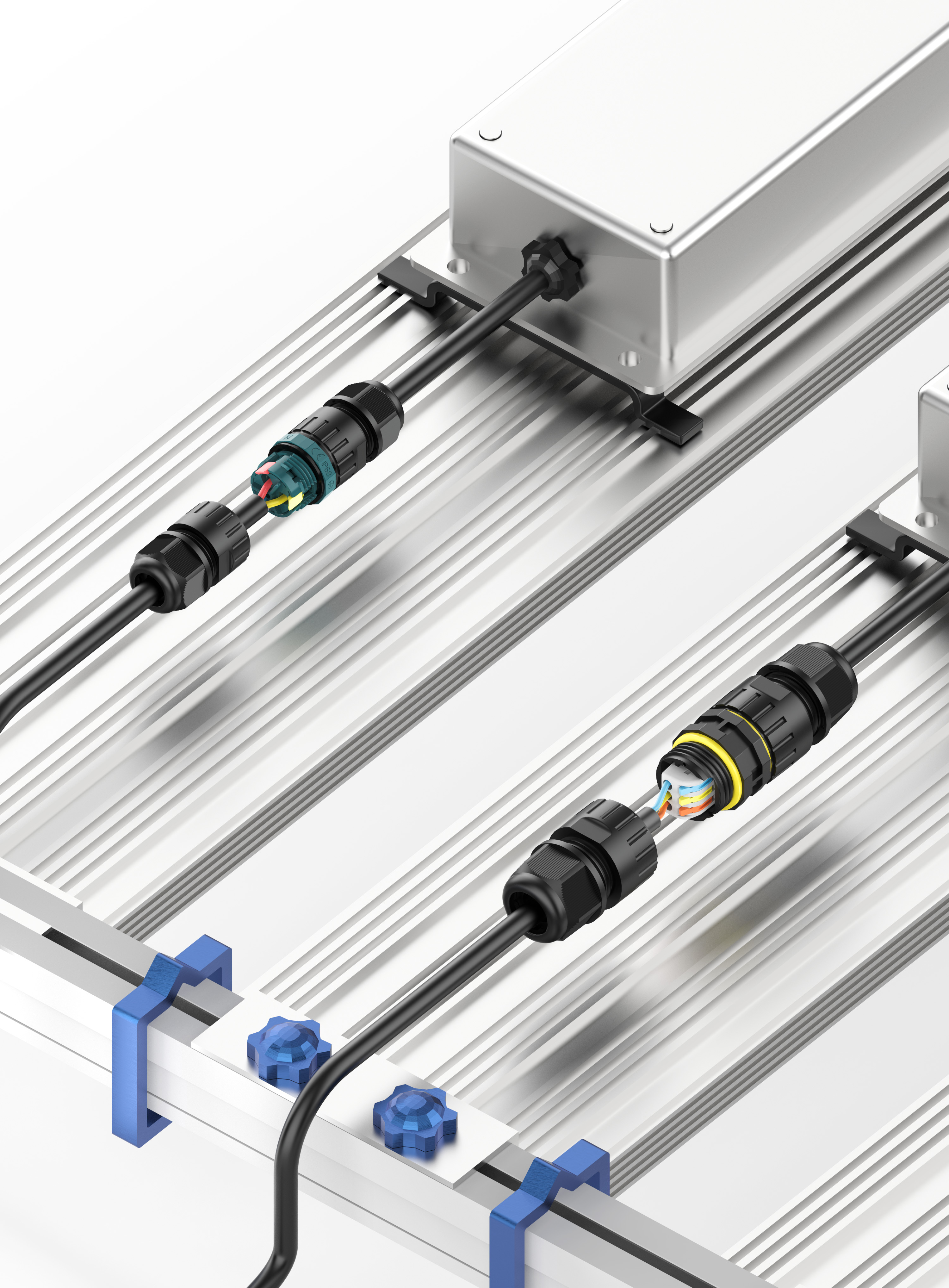

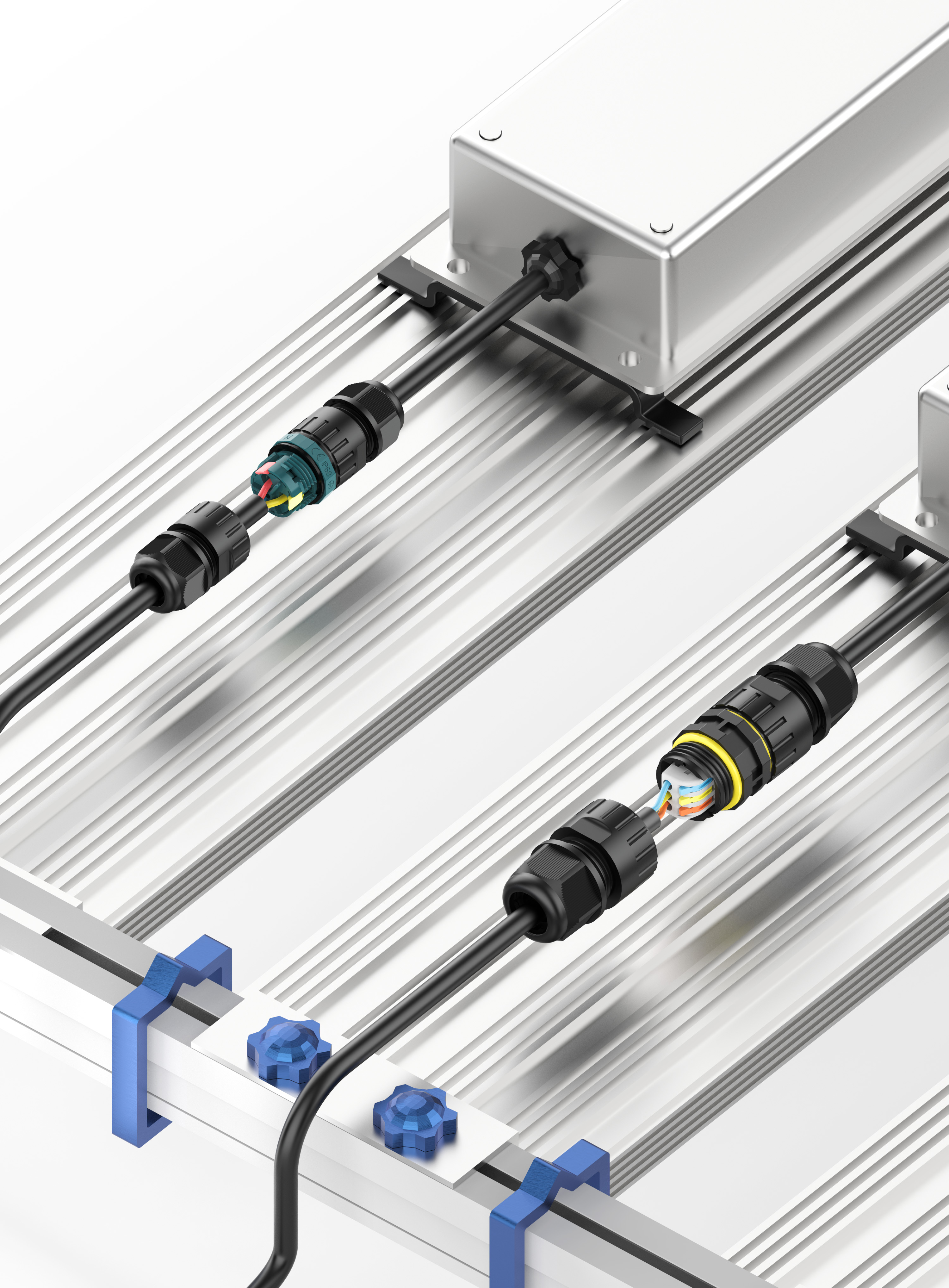

The importance of connectors like the M12 in industrial automation cannot be overstated. They play a vital role in facilitating communication and power distribution between sensors, actuators, and control systems, forming the backbone of automated processes. M12 connectors are designed to withstand the demanding conditions often found in industrial settings, including exposure to dust, moisture, and mechanical stress.

Key features of M12 connectors include their high durability, resistance to extreme temperatures, and various configurations that cater to different applications. These attributes make them particularly well-suited for use in robotics, where reliability and performance are paramount. As industries continue to evolve, the M12 connector remains an indispensable element, ensuring seamless integration and functionality across a wide range of applications.

M12 connectors are designed to meet the rigorous demands of industrial automation and robotics. Here are some of their key features:

1. Durability in Stressful Environments: M12 connectors are engineered to withstand harsh industrial conditions, ensuring reliable connectivity even in the most challenging environments.

2. Resistance to Mechanical Stress: These connectors exhibit excellent resistance to mechanical stress, making them suitable for applications where vibration and movement are prevalent, such as in robotic systems.

3. High Temperature Resistance: M12 connectors can operate effectively over a wide range of temperatures, ensuring functionality in both high heat and low-temperature environments, which is critical for machinery that may be exposed to extreme conditions.

4. Protection Against Dust and Moisture: M12 connectors are designed with robust sealing mechanisms that protect against environmental factors. They often feature IP (Ingress Protection) ratings, which indicate their effectiveness against dust and moisture ingress.

5. IP Ratings Explained: The IP rating system provides a standardized way to classify the degree of protection offered by connectors. For instance, an IP67 rating means the connector is dust-tight and can withstand immersion in water up to 1 meter deep for 30 minutes.

6. Applications in Harsh Environments: Due to these features, M12 connectors are widely used in industries such as automotive, food and beverage, and manufacturing, where reliable performance in tough conditions is essential for operational efficiency.

Their robust design and durability make them ideal for use in dynamic and demanding environments, which are characteristic of industrial robotics. These connectors facilitate reliable communication between various components, such as sensors, actuators, and controllers, ensuring seamless operation and coordination within the robotic system.

In robotic applications, M12 connectors are often used for power supply and signal transmission. For instance, they can connect sensors that gather data about the robot’s surroundings to the control unit, enabling real-time processing and decision-making. The ability to withstand mechanical stress and temperature fluctuations makes M12 connectors particularly suitable for robots operating in factories or warehouses, where they are exposed to vibrations and varying environmental conditions.

Examples of M12 connectors in robotic applications include their use in collaborative robots (cobots) that work alongside human operators. These connectors ensure safe and efficient data exchange, enhancing the functionality and versatility of robotic systems. Furthermore, M12 connectors are integral to automated guided vehicles (AGVs) that navigate complex pathways, demonstrating their essential role in advancing robotics within industrial automation.

Case studies exemplifying successful implementations of M12 connectors in industrial controls underscore their significance. In a manufacturing facility, the use of M12 connectors streamlined connections between various control devices, resulting in reduced installation time and improved system reliability. As industries continue to evolve, the demand for efficient, durable, and high-performance connectors like the M12 will only increase, solidifying their position as a cornerstone of modern industrial automation.

-

Fast and Convenient

-

Customization

- Need a technical consultant to answer your questions?

-

-

Hot Promoted Products

Recommend current hot products to you