[{"CategoryId":271,"CategoryName":"By Series","ParentId":0,"Imageurl":""},{"CategoryId":272,"CategoryName":"By Size","ParentId":0,"Imageurl":""},{"CategoryId":273,"CategoryName":"By Number of Pins","ParentId":0,"Imageurl":""},{"CategoryId":274,"CategoryName":"By Application","ParentId":0,"Imageurl":""},{"CategoryId":275,"CategoryName":"By Wiring","ParentId":0,"Imageurl":""},{"CategoryId":276,"CategoryName":"Customization","ParentId":0,"Imageurl":""},{"CategoryId":277,"CategoryName":"By Material","ParentId":0,"Imageurl":""},{"CategoryId":278,"CategoryName":"LP Series","ParentId":271,"Imageurl":"2025/07/20250724101928371.jpg?TFDns7vliJcuYmlwLjI1NTUuanBn"},{"CategoryId":1319,"CategoryName":"SF Series","ParentId":271,"Imageurl":"2025/09/20250913181601452.jpg?U0Y2LTgtMTDlhajlrrbnpo8uanBn"},{"CategoryId":1245,"CategoryName":"SP Series","ParentId":271,"Imageurl":"2025/09/20250913181428839.jpg?U1AuanBn"},{"CategoryId":279,"CategoryName":"Self Locking Series","ParentId":271,"Imageurl":"2024/09/20240905134920982.png?U2VsZiBMb2NraW5nIFNlcmllcw=="},{"CategoryId":280,"CategoryName":"Waterproof Cable Connector","ParentId":271,"Imageurl":"2024/09/20240905142754587.png?V2F0ZXJwcm9vZiBDYWJsZSBDb25uZWN0b3I="},{"CategoryId":281,"CategoryName":"Junction Box","ParentId":271,"Imageurl":"2024/09/20240905155939966.png?5o6l57q/55uS57O75YiXIDYxM3g2MTMucG5n"},{"CategoryId":1222,"CategoryName":"Cable Gland","ParentId":271,"Imageurl":"2025/03/20250320135315907.jpg?Y2FibGUtZ2xhbmQuanBn"},{"CategoryId":282,"CategoryName":"Energy Storage Connector","ParentId":271,"Imageurl":"2024/09/20240905143234262.png?RW5lcmd5IFN0b3JhZ2UgQ29ubmVjdG9y"},{"CategoryId":1161,"CategoryName":"PV Connector","ParentId":271,"Imageurl":"2024/09/20240905143119031.png?UFYgQ29ubmVjdG9y"},{"CategoryId":1351,"CategoryName":"M29","ParentId":272,"Imageurl":""},{"CategoryId":1170,"CategoryName":"M28","ParentId":272,"Imageurl":"2024/12/20241204113448729.png?TTI4IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1169,"CategoryName":"M25","ParentId":272,"Imageurl":"2024/12/20241204113352959.png?TTI1IGNpcmN1bGFyIHBsYXN0aWMgd2lyZSBjb25uZWN0b3I="},{"CategoryId":319,"CategoryName":"M24","ParentId":272,"Imageurl":"2024/12/20241204113237802.png?TTI0IEluZHVzdHJpYWwgd2F0ZXJwcm9vZiBjb25uZWN0b3I="},{"CategoryId":1168,"CategoryName":"M23","ParentId":272,"Imageurl":"2024/12/20241204112141563.png?TTIzIHdhdGVycHJvb2YgcGx1ZyBjb25uZWN0b3Jz"},{"CategoryId":1350,"CategoryName":"M21","ParentId":272,"Imageurl":""},{"CategoryId":318,"CategoryName":"M20","ParentId":272,"Imageurl":"2024/12/20241204112034702.png?TTIwIGNpcmN1bGFyIGNvbm5lY3Rvcg=="},{"CategoryId":1167,"CategoryName":"M19","ParentId":272,"Imageurl":"2024/12/20241204111937164.png?TTE5IHdhdGVycHJvb2Ygd2lyZSBjb25uZWN0b3Jz"},{"CategoryId":1349,"CategoryName":"M17","ParentId":272,"Imageurl":""},{"CategoryId":293,"CategoryName":"M16","ParentId":272,"Imageurl":"2024/12/20241204111827969.png?TTE2IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1166,"CategoryName":"M15","ParentId":272,"Imageurl":"2024/12/20241204111717740.png?TTE1IG1hbGUgYW5kIGZlbWFsZSBjb25uZWN0b3Jz"},{"CategoryId":1348,"CategoryName":"M13","ParentId":272,"Imageurl":""},{"CategoryId":292,"CategoryName":"M12","ParentId":272,"Imageurl":"2024/12/20241204111548642.png?TTEyIFdhdGVycHJvb2YgTTEyIENvbm5lY3Rvcg=="},{"CategoryId":1347,"CategoryName":"M10","ParentId":272,"Imageurl":""},{"CategoryId":1346,"CategoryName":"M8","ParentId":272,"Imageurl":""},{"CategoryId":1345,"CategoryName":"M6","ParentId":272,"Imageurl":""},{"CategoryId":335,"CategoryName":"TYPE-C","ParentId":273,"Imageurl":"2024/08/20240803175816209.jpg?TFAxNi1UWVBFLUPph5HlsZ7ms5XlhbAuanBn"},{"CategoryId":334,"CategoryName":"Fiber","ParentId":273,"Imageurl":"2024/07/20240730100446602.png?TFAyNC1GSUJFUig2KSAyMDB4MjAwIC0g5Ymv5pysLnBuZw=="},{"CategoryId":333,"CategoryName":"HDMI","ParentId":273,"Imageurl":"2024/07/20240730100616849.png?TFAyNC1IRE1JKDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":332,"CategoryName":"USB","ParentId":273,"Imageurl":"2024/07/20240730100646405.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":331,"CategoryName":"RJ45","ParentId":273,"Imageurl":"2024/07/20240730100713409.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlr7nmjqUucG5n"},{"CategoryId":1335,"CategoryName":"26 Pins","ParentId":273,"Imageurl":"2025/09/20250908170725350.jpg?U1AyOS0yNlDkuKTlrZTluqfmraPoo4UgODAweDgwMC5qcGc="},{"CategoryId":330,"CategoryName":"24 Pins","ParentId":273,"Imageurl":"2024/07/20240730101220115.jpg?TFAyNC0yNFDpnaLmnb/ph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1334,"CategoryName":"20 Pins","ParentId":273,"Imageurl":"2025/09/20250908170702461.jpg?U0YyOC0yMFDpnaLmnb8gODAweDgwMC5qcGc="},{"CategoryId":329,"CategoryName":"19 Pins","ParentId":273,"Imageurl":"2024/07/20240730101243254.jpg?TFAyNC0xOVDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1333,"CategoryName":"18 Pins","ParentId":273,"Imageurl":"2025/09/20250908170641433.jpg?U0YyOC0xOFDlr7nmjqUgODAweDgwMC5qcGc="},{"CategoryId":1344,"CategoryName":"17 Pins","ParentId":273,"Imageurl":""},{"CategoryId":1332,"CategoryName":"16 Pins","ParentId":273,"Imageurl":"2025/09/20250908170620266.jpg?U0YyOC0xNlDpnaLmnb/luqflj43oo4UgODAweDgwMC5qcGc="},{"CategoryId":1215,"CategoryName":"14 Pins","ParentId":273,"Imageurl":"2024/08/20240808120100973.jpg?TFAyMC0xNFDms5XlhbDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":328,"CategoryName":"12 Pins","ParentId":273,"Imageurl":"2024/07/20240730101400996.png?TFAyNC0xMlDms5XlhbDloZHmlpnlj43oo4XmrL4ucG5n"},{"CategoryId":327,"CategoryName":"10 Pins","ParentId":273,"Imageurl":"2024/07/20240730101422023.jpg?TFAyNC0xMFDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":326,"CategoryName":"9 Pins","ParentId":273,"Imageurl":"2024/07/20240730101545901.jpg?TFAyMC05UC3lr7nmj5ItMy5qcGc="},{"CategoryId":325,"CategoryName":"8 Pins","ParentId":273,"Imageurl":"2024/07/20240730101729864.jpg?TFAxNi04UOmdouadv0zph5HlsZ7mraPoo4UuanBn"},{"CategoryId":324,"CategoryName":"7 Pins","ParentId":273,"Imageurl":"2024/07/20240730101805407.jpg?TFAxNi03UOazleWFsFDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":323,"CategoryName":"6 Pins","ParentId":273,"Imageurl":"2024/07/20240730101848277.png?TFAxMi02UCDlj43oo4UgMi5wbmc="},{"CategoryId":322,"CategoryName":"5 Pins","ParentId":273,"Imageurl":"2024/07/20240730102001465.jpg?TFAyNC01UOWFrOaPklPph5HlsZ7lj43oo4XplIHnur/mrL4uanBn"},{"CategoryId":321,"CategoryName":"4 Pins","ParentId":273,"Imageurl":"2024/07/20240730102053511.png?TFAyMC00UOazleWFsOWhkeaWmeato+ijhS5wbmc="},{"CategoryId":320,"CategoryName":"3 Pins","ParentId":273,"Imageurl":"2024/07/20240730102122414.jpg?TFAyOC0zUOWvueaPkuWhkeaWmeato+ijhS5qcGc="},{"CategoryId":295,"CategoryName":"2 Pins","ParentId":273,"Imageurl":"2024/07/20240730102152158.jpg?TFAyOC0yUOazleWFsOWhkeaWmeato+ijhS5qcGc="},{"CategoryId":294,"CategoryName":"1 Pin","ParentId":273,"Imageurl":"2024/12/20241202141836844.png?ZW5lcmd5IHN0b3JhZ2UgY29ubmVjdG9y"},{"CategoryId":315,"CategoryName":"Signal Connector","ParentId":274,"Imageurl":"2024/07/20240730133750759.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":297,"CategoryName":"Data Connector","ParentId":274,"Imageurl":"2024/07/20240730093457270.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":296,"CategoryName":"Power Connector","ParentId":274,"Imageurl":"2024/08/20240803175721975.jpg?TFAxNi00UCg5KS5qcGc="},{"CategoryId":338,"CategoryName":"Crimping Type","ParentId":275,"Imageurl":"2024/12/20241202143025954.png?TFAxMi0yUOWvueaPkumHkeWxnuato+ijhSA3NTB4NzUwLnBuZw=="},{"CategoryId":336,"CategoryName":"Solder Type","ParentId":275,"Imageurl":"2024/12/20241202142826795.png?TFAyNC0y6Iqv54SK5o6l5aGR5paZ5qy+5rOV5YWw5Y+N6KOFc2t1LnBuZw=="},{"CategoryId":337,"CategoryName":"Screw Type","ParentId":275,"Imageurl":"2024/12/20241202142506193.png?TFAxMi0yUOazleWFsFDph5HlsZ7plIHnur/lj43oo4UucG5n"},{"CategoryId":298,"CategoryName":"Screwless Type","ParentId":275,"Imageurl":"2024/05/20240529162027688.jpg?5b+r5o6l57O75YiXLmpwZw=="},{"CategoryId":301,"CategoryName":"Mix Pins","ParentId":276,"Imageurl":"2024/07/20240730102324120.jpg?TFAyOC0zUOazleWFsOWhkeaWmeato+ijhS0xLmpwZw=="},{"CategoryId":1330,"CategoryName":"Color","ParentId":276,"Imageurl":""},{"CategoryId":317,"CategoryName":"Metal + Plastic","ParentId":277,"Imageurl":"2024/08/20240803180032739.jpg?TFAxMi00UOazleWFsOmHkeWxnuWPjeijhS5qcGc="},{"CategoryId":316,"CategoryName":"All Metal","ParentId":277,"Imageurl":"2024/11/20241121135153910.png?TFAxMi0yUOazleWFsOasvumUgee6vy5wbmc="},{"CategoryId":300,"CategoryName":"All Plastic","ParentId":277,"Imageurl":"2024/08/20240803180224853.png?TFAxMi00UCDlj43oo4UgNy5wbmc="},{"CategoryId":287,"CategoryName":"LP12","ParentId":278,"Imageurl":"2024/12/20241203141919861.png?TFAxMiBlbGVjdHJpY2FsIHdhdGVycHJvb2YgY29ubmVjdG9ycw=="},{"CategoryId":283,"CategoryName":"LP16","ParentId":278,"Imageurl":"2024/12/20241203141926793.png?TFAxNiB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":286,"CategoryName":"LP20","ParentId":278,"Imageurl":"2024/12/20241203140522654.png?TFAyMCBJbmR1c3RyaWFsIHdhdGVycHJvb2YgY29ubmVjdG9y"},{"CategoryId":285,"CategoryName":"LP24","ParentId":278,"Imageurl":"2024/12/20241203140638274.jpg?TFAyNCB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":284,"CategoryName":"LP28","ParentId":278,"Imageurl":"2024/12/20241203140831377.png?TFAyOCBXYXRlcnByb29mIENhYmxlIENvbm5lY3Rvcg=="},{"CategoryId":303,"CategoryName":"M15MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095659595.jpg?TTE1TUYtM1AuanBn"},{"CategoryId":304,"CategoryName":"M19MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095626837.jpg?6Z2i5p2/55m95bqVIC0g5Ymv5pysLmpwZw=="},{"CategoryId":305,"CategoryName":"M23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095548936.jpg?RVctTTIzTVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":307,"CategoryName":"M28MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095408770.jpg?RVctTTI4TVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":306,"CategoryName":"P25MP/MF","ParentId":279,"Imageurl":"2024/07/20240729185729105.png?UDI1LS3oiq/mlbAt5aSW57q/55u05b6E5Zu+IDIwMHgyMDAucG5n"},{"CategoryId":1209,"CategoryName":"P23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730100244127.png?UDIzLnBuZw=="},{"CategoryId":302,"CategoryName":"Screw Connector Series","ParentId":280,"Imageurl":"2024/12/20241203142740551.png?U2NyZXcgQ29ubmVjdG9yIFNlcmllcw=="},{"CategoryId":289,"CategoryName":"Screwless Connector Series","ParentId":280,"Imageurl":"2024/09/20240905144436844.png?U2NyZXdsZXNzIENvbm5lY3RvciBTZXJpZXM="},{"CategoryId":290,"CategoryName":"2068 Serie","ParentId":281,"Imageurl":"2024/07/20240730094848584.png?RVctTTIwNjgtNVQucG5n"},{"CategoryId":1536,"CategoryName":"2068N Serie","ParentId":281,"Imageurl":"2026/01/20260116110540406.png?TTIwNjhOLTJUICAoMikucG5n"},{"CategoryId":1538,"CategoryName":"2068R Serie","ParentId":281,"Imageurl":"2026/02/20260206151256783.png?RVctTTIwNjhSLTFUICgxKS5wbmc="},{"CategoryId":308,"CategoryName":"2068S Serie","ParentId":281,"Imageurl":"2024/07/20240729190104148.jpg?55m95bqVMy5qcGc="},{"CategoryId":309,"CategoryName":"2068L Serie","ParentId":281,"Imageurl":"2024/07/20240729190043564.jpg?55m95bqVMi5qcGc="},{"CategoryId":310,"CategoryName":"2068XL Serie","ParentId":281,"Imageurl":"2024/07/20240730094724530.jpg?MTAuanBn"},{"CategoryId":1159,"CategoryName":"350A","ParentId":282,"Imageurl":"2024/07/20240729190329212.jpg?RTMwMC0zNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":1158,"CategoryName":"300A","ParentId":282,"Imageurl":"2024/07/20240729190349998.jpg?RTMwMOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":341,"CategoryName":"250A","ParentId":282,"Imageurl":"2024/07/20240729190408955.jpg?RTEwMC0yNTDlj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":340,"CategoryName":"200A","ParentId":282,"Imageurl":"2024/07/20240729190435882.jpg?RTI1MOS4jeWPr+aXi+i9rOieuuafsem7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":339,"CategoryName":"150A","ParentId":282,"Imageurl":"2024/07/20240729190456384.jpg?RTEwMC0yNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":311,"CategoryName":"120A","ParentId":282,"Imageurl":"2024/07/20240729190538607.jpg?RTI1MOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":312,"CategoryName":"100A","ParentId":282,"Imageurl":"2024/07/20240729190551775.jpg?RTEwMC0yNTDkuI3lj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":313,"CategoryName":"70A","ParentId":282,"Imageurl":"2024/07/20240729190619040.jpg?RTUw5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S6buR6Imy5aWX6KOFU0tVXy5qcGc="},{"CategoryId":314,"CategoryName":"50A","ParentId":282,"Imageurl":"2024/07/20240729190633170.jpg?RTUwLTcw5LiN5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S5qmZ6Imy5aWX6KOFU0tVLmpwZw=="},{"CategoryId":1533,"CategoryName":"LP20","ParentId":298,"Imageurl":""},{"CategoryId":1526,"CategoryName":"M25B","ParentId":298,"Imageurl":""},{"CategoryId":299,"CategoryName":"P25","ParentId":298,"Imageurl":"2024/05/20240529162134233.jpg?UDIzLjIuanBn"},{"CategoryId":1531,"CategoryName":"P23","ParentId":298,"Imageurl":""},{"CategoryId":1107,"CategoryName":"P20","ParentId":298,"Imageurl":"2024/09/20240909134224415.png?UDIwLS3oiq/mlbAt5aSW57q/55u05b6E5Zu+LSA2MTN4NjEzLnBuZw=="},{"CategoryId":1530,"CategoryName":"P25X","ParentId":298,"Imageurl":""},{"CategoryId":1529,"CategoryName":"P25T","ParentId":298,"Imageurl":""},{"CategoryId":1528,"CategoryName":"P20X","ParentId":298,"Imageurl":""},{"CategoryId":1527,"CategoryName":"P20T","ParentId":298,"Imageurl":""},{"CategoryId":1165,"CategoryName":"65A","ParentId":1161,"Imageurl":"2024/07/20240729190717746.jpg?MTBtbcKy6Z2i5p2/5bel5YW36Kej6ZSB5YWs5o+S5aS0LmpwZw=="},{"CategoryId":1164,"CategoryName":"45A","ParentId":1161,"Imageurl":"2024/07/20240729190731167.jpg?Nm1twrLnur/nq6/lt6Xop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1163,"CategoryName":"35A","ParentId":1161,"Imageurl":"2024/07/20240729190743086.jpg?NG1twrLnur/nq6/lt6Xlhbfop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1201,"CategoryName":"25A","ParentId":1161,"Imageurl":"2024/07/20240729190756464.jpg?Mi41bW3Csue6v+err+W3peWFt+ino+mUgeWFrOaPkuWktC5qcGc="},{"CategoryId":1223,"CategoryName":"PG Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1243,"CategoryName":"PG Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1224,"CategoryName":"M Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1244,"CategoryName":"M Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1247,"CategoryName":"SP13","ParentId":1245,"Imageurl":""},{"CategoryId":1246,"CategoryName":"SP17","ParentId":1245,"Imageurl":""},{"CategoryId":1327,"CategoryName":"SP21","ParentId":1245,"Imageurl":""},{"CategoryId":1326,"CategoryName":"SP29","ParentId":1245,"Imageurl":""},{"CategoryId":1320,"CategoryName":"SF6","ParentId":1319,"Imageurl":""},{"CategoryId":1321,"CategoryName":"SF8","ParentId":1319,"Imageurl":""},{"CategoryId":1328,"CategoryName":"SF10","ParentId":1319,"Imageurl":""},{"CategoryId":1322,"CategoryName":"SF12","ParentId":1319,"Imageurl":""},{"CategoryId":1323,"CategoryName":"SF16","ParentId":1319,"Imageurl":""},{"CategoryId":1324,"CategoryName":"SF20","ParentId":1319,"Imageurl":""},{"CategoryId":1325,"CategoryName":"SF28","ParentId":1319,"Imageurl":""}]

Using Industrial Connectors In Communication Chassis In Industrial Settings-医疗行业新能源行业通讯行业工控设备机器人行业照明行业产品知识媒体报道公司新闻常见问题答疑产品基础知识连接器选型产品证书宣传资料安装视频安装流程书三维图产品规格书防水接线端子储能连接器防水接线盒数据连接器电源连接器信号连接器Waterproof Cable ConnectorEnergy Storage ConnectorJunction BoxData ConnectorSignal ConnectorPower ConnectorMedical IndustryNew Energy IndustryCommunications IndustryIndustrial Control EquipmentRobotics IndustryLighting IndustryFAQProduct BasicsConnector SelectionProduct CertificatePropagandaInstallation VideoInstallation Procedure BookThree Dimensional MapProduct SpecificationsProduct KnowledgeMediaCompany NewsPV ConnectorCable GlandLighting Connector

Communication systems are essential for our everyday lives, enabling us to connect and communicate with each other seamlessly. However, in order for these systems to function effectively, they require powerful and reliable power connections. This is where industrial connectors play a crucial role.

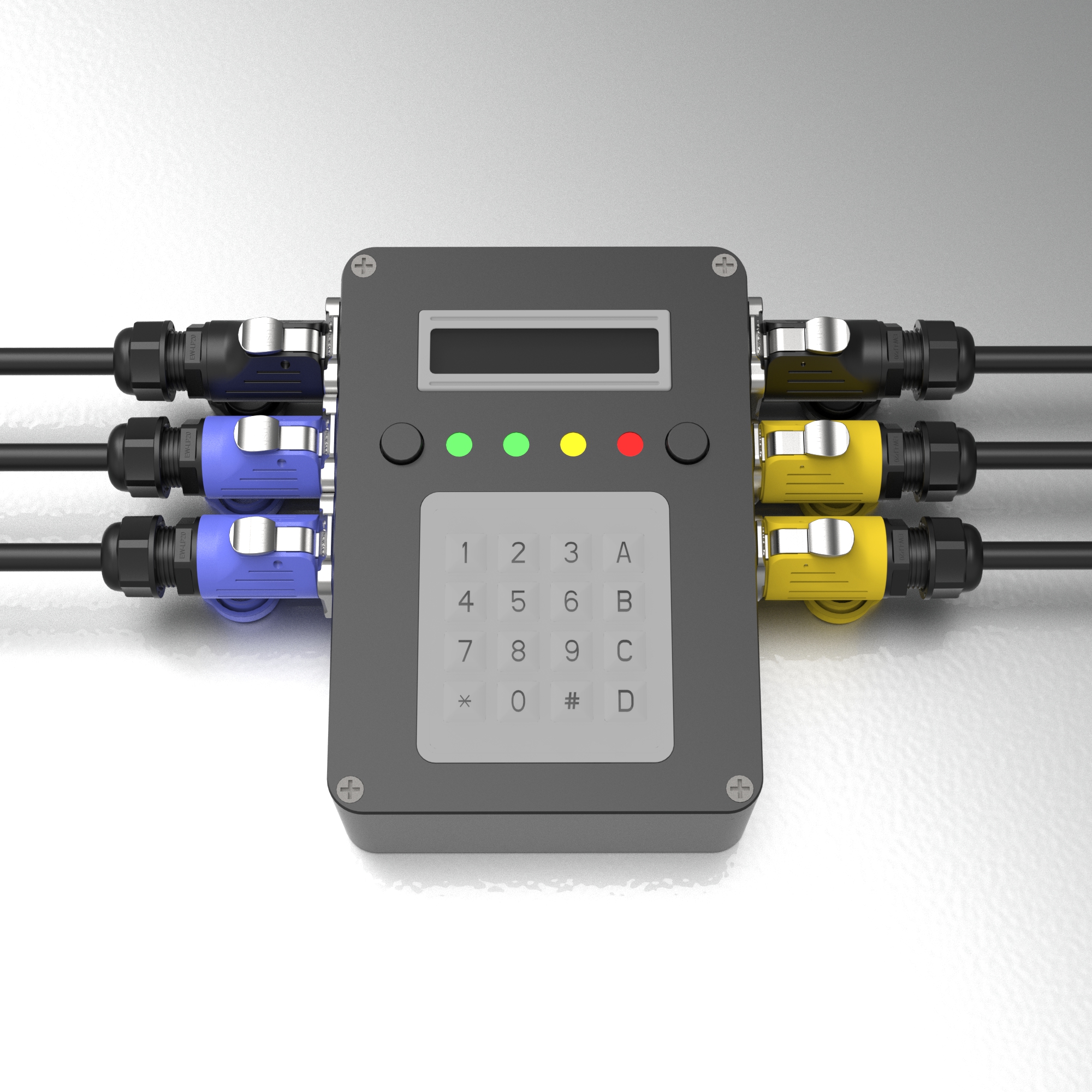

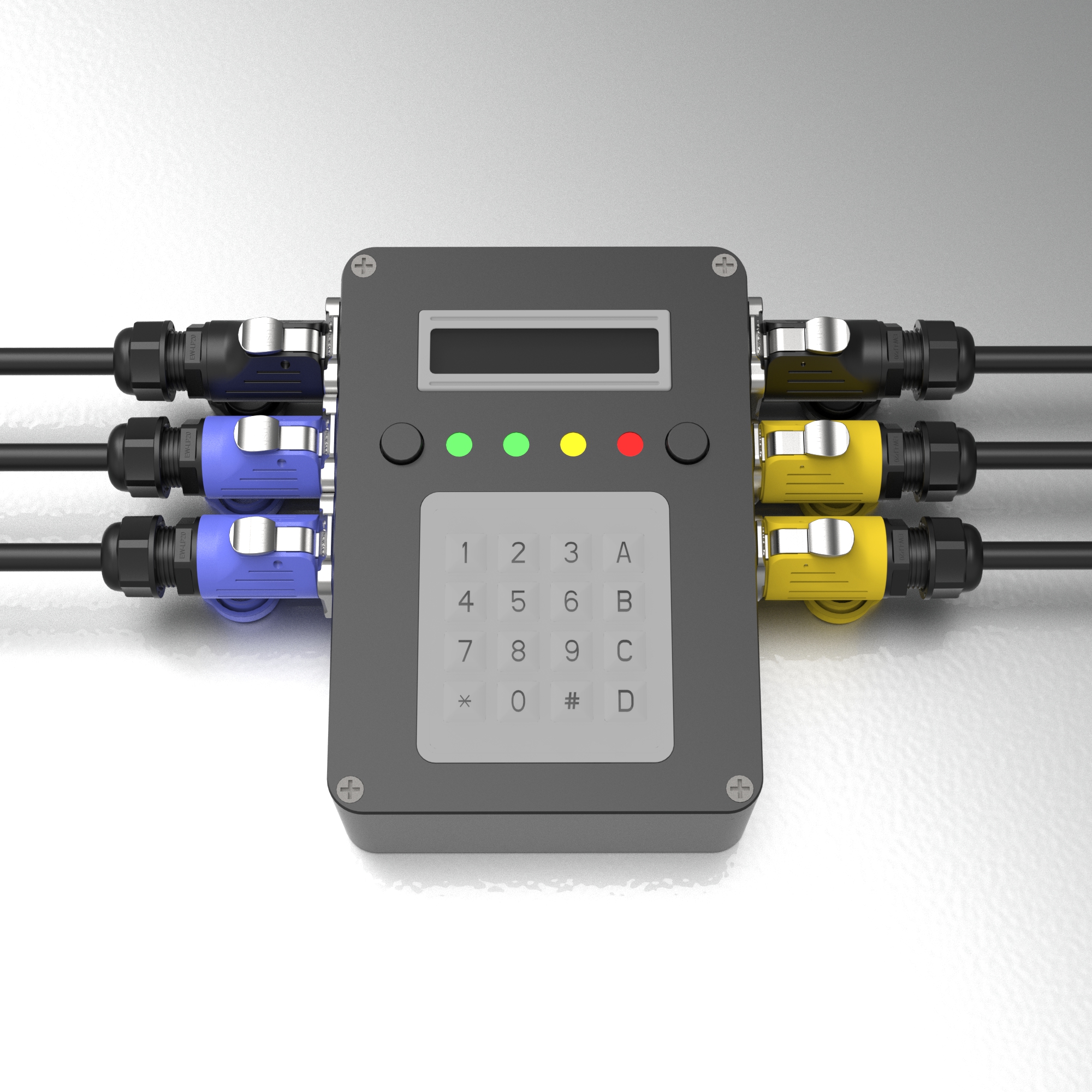

Industrial connectors are specially designed to provide secure and stable power connections even in the most challenging environments. They are built to withstand extreme weather conditions, high temperatures, and rough handling, making them ideal for use in communication chassis.

In this case study, we will explore the importance of powerful and reliable power connections in communication chassis and the key role that industrial connectors play in ensuring the smooth operation of these systems. We will also analyze two real-life scenarios where the use of industrial connectors proved to be crucial for the success of the communication chassis.

The features of industrial connectors such as durability, high ingress protection ratings, and resistance to vibration and shock make them highly reliable for ensuring uninterrupted power supply in communication chassis. In addition, industrial connectors are designed to provide secure and robust connections, minimizing the risk of power failure or data loss.

Scenario 1: Communication chassis in extreme weather conditions

In extreme weather conditions, such as heavy rain, snow, and high winds, communication chassis are at risk of being damaged if not properly protected. This is where the use of waterproof connectors becomes crucial. Industrial connectors designed for waterproofing provide a reliable and secure power connection that can withstand harsh environments.

3.Solid and stable connection, no fear of vibration stress source

In this scenario, a telecommunication company is installing communication chassis in a remote location prone to extreme weather conditions. They choose to use communication chassis waterproof connectors to ensure the reliability and durability of the power connections. These connectors are designed to provide a tight seal that prevents water and moisture from entering the chassis, protecting the sensitive electronics inside.

The industrial connectors used in this scenario have features such as IP67 or IP68 ratings, which indicate their level of protection against water and dust ingress. These connectors are also made of high-quality materials that can withstand temperature fluctuations, ensuring they remain functional in extreme weather conditions.

Scenario 2: Communication chassis in industrial settings

In industrial settings, communication chassis are often exposed to harsh environmental conditions such as extreme temperatures, moisture, dust, and vibrations. These challenging conditions can compromise the performance and reliability of power connections, leading to frequent maintenance and downtime.

In industrial settings, communication chassis are often exposed to harsh environmental conditions such as extreme temperatures, moisture, dust, and vibrations. These challenging conditions can compromise the performance and reliability of power connections, leading to frequent maintenance and downtime.

Industrial connectors play a crucial role in ensuring the robustness and durability of power connections in communication chassis. These connectors are designed to withstand the rigors of industrial environments, offering features such as IP67 or higher ingress protection ratings, rugged construction, and high resistance to temperature variations and chemical exposure.

By using industrial connectors in communication chassis in industrial settings, companies can benefit from increased reliability, reduced maintenance costs, and improved operational efficiency. The connectors provide a secure and stable connection that can withstand the demands of industrial applications, ensuring uninterrupted communication and data transmission.

or example, a manufacturing facility that relies on communication chassis for monitoring and controlling equipment can greatly benefit from using industrial connectors. These connectors will ensure that power connections remain secure and reliable, even in the presence of dust, moisture, and vibrations. This will help the facility minimize downtime, improve productivity, and maintain a competitive edge in the market.

-

Fast and Convenient

-

Customization

- Need a technical consultant to answer your questions?

-

-

Hot Promoted Products

Recommend current hot products to you